We engineered tomorrow for

33

Bespoke tooling solutions

66

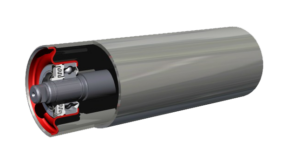

S-Rim bearing housing variants

100%

On-time worldwide supply

Project Objective

Joy Global have been a longstanding customer of GMS’ for over 20 years, and we have worked closely on many international capital projects, supplying component parts for their underground mining and tunnelling systems.

One notable project was the recent Crossrail addition to the London Underground, which was one of the most substantial railway infrastructure projects in Europe and one of the largest single investments taken in the UK.

This project has ran since 2009 coming to a close in 2021, with Joy Global supplying the tunnelling conveyors required for the extraction of the excavated material.

Prior to the project Joy Global had wished to re-design the endcap bearing housings that are an essential component in the conveyors in order to improve their function and durability. However, they had not been able to achieve these benefits at the price point they required to capitalise on any competitive advantage the new design would yield.

Project Method

GMS’s engineering team worked closely with Joy Global in designing the new S rim bearing housing, visiting the plants (Wingfield, Alabama, USA | Moss Vale, Sydney, AUS | Southwick, Sunderland, UK) that would make use of this new product. Spending time collaborating with their respective design teams to develop the S rim range.

By providing design-for-manufacture (DFM) guidance GMS was able to assist and ensure that the resulting part was both efficient to manufacture and cost-effective to purchase, whilst providing the improved rigidity and structural benefits required of it.

Project Outcome

The S rim bearing housing was such a success and provided such a competitive advantage, that Joy Global wanted to manufacture and offer this product group-wide throughout their divisions. Culminating with GMS manufacturing 33 different press tools capable of manufacturing 66 different S rim bearing housing variants across the entire range, a range that GMS now supplies worldwide.

This product allowed Joy Global to utilise un-used production capacity within its global plants and in turn supply their product worldwide, enabling them to better compete competitively on a truly global basis, winning other tunnelling mining projects and maintaining their market leader status in Eurasia, whilst establishing themselves as a serious contender in the global underground mining arena.

This status did not go unnoticed and in 2017 Joy Global joined the Komatsu Mining Corp., lending their expertise in crushing and conveyor systems to provide a more holistic underground mining solution.

In 2013 GMS were proud to receive the Joy Global Premier Supplier award for achieving 100% on-time delivery with zero defects across all Joy Global’s manufacturing facilities worldwide.